Compound Angles

By Rick Christopherson

Update:

This article was originally written in 1998. I have wanted to

rewrite this article for many years with better graphics and an

online calculator. When Festool-USA asked me to write the owner's

manual for their (then) new Kapex mitersaw in 2009, I finally had

the opportunity to rework this information. However, it was

formatted for PDF output, not HTML. So I did not want to completely

replace this HTML version with a straight link to the PDF. The

information between the two is the same, but the PDF version may use

different variable names, and includes more information than this

HTML version. It also includes additional information regarding

cutting crown moulding using standard miter techniques as well as

compound miter techniques. It also explains how to apply this

information to other applications beyond simple crown moulding.

I recommend reading the PDF instead of this HTML version. If your

internet browser is setup to view PDFs directly in the browser and

the calculator doesn't work for you, then right-click on the link

below and save the file on your computer. Some people have reported

that the calculator does not work on their computer, but I have not

had enough comments to determine under what conditions this may be

happening.

This Compound

Miter (PDF) document is the 3 pages extracted directly from

the Festool Kapex manual. Even if you don't own a Festool Kapex

mitersaw, you may still want to read the entire Kapex

Supplemental Owner's Manual because it contains additional

information that can be applied to your brand of miter saw, such as

calibrating the miter settings using the 4-cut calibration method,

and includes a built-in calculator for that as well.

While there are several different methods for cutting mouldings,

sometimes the best method is to use compound angle settings on a

miter saw, radial arm saw, or a table saw. This isn't necessarily

limited to cutting mouldings though. There are many other

applications where compound miter settings are needed, like the roof

of a doll house for example. Below is a set of equations for

determining the compound angle settings for your miter saw. These

equations will work for any compound angle, but I use crown moulding

around a ceiling as my example, since this is easy to visualize.

In their original form, the equations are very simple and only

use

two variables. To make the equations easier to use in the shop, I

have rearranged the equations in two different forms. These are

all

the same equations, but they are just mathematically

manipulated to help you out. Which equation best suits your needs

will depend on how fluent you are in mathematics, and what

variables

are known when you start. (I have also compiled a

quick reference page to

keep

in your shop. This is just a duplication of the graphic images

shown

below.)

Getting Started

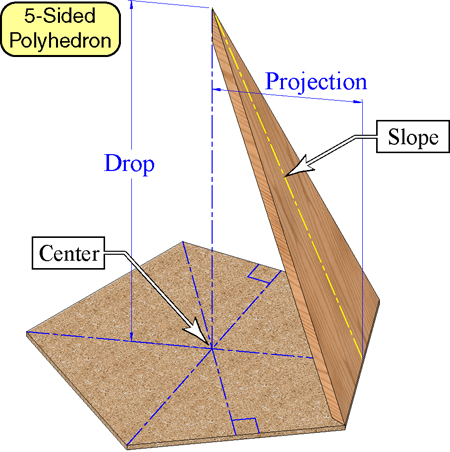

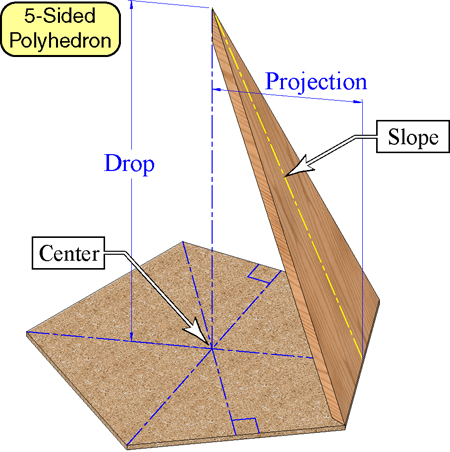

As I stated, there are only two variables needed to use these

equations. The first variable deals with the angle of the room,

picture frame, roof, or how many sides a box has. I have setup my

equations in such a way that it doesn't matter whether you are

making

an inside corner or an outside corner. This is where many

woodworkers

make mistakes because we are not accustomed to working with

numbers

greater than 90°. For example, if you were placing crown

moulding around the top of a square column, other equations would

require you to use the "true" angle of 270°, and if you

didn't,

the results would be abnormal miter settings. The equations I

derived

use the angles the way a woodworker sees them, not a

mathematician.

FlatMiter

FlatMiter

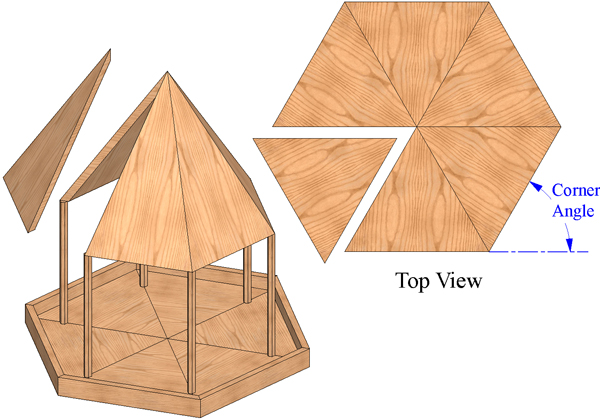

I will call this first variable the FlatMiter (1/2 the

"Corner Angle" used in the PDF version). This variable

is the angle which you would normally set your saw to, in order to

miter a piece of flat moulding. In other words, if you were

putting

crown moulding up around a square room, the FlatMiter would be

45°. The table to the right shows the FlatMiter values

based on how many sides a room or box has.

If your application doesn't fit into the category of being able

to

count the number of sides a box has, you can simply calculate the

FlatMiter variable. Let's say you measured the corner of a box and

found it to be 94° instead of the normal 90°. Then your

FlatMiter variable would be 47°, which is ½ of 94

°.

Remember, with the exception of a triangular frame or the example

above, your FlatMiter variable should always be less than 45°.

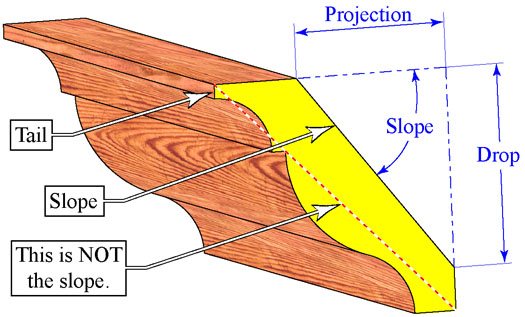

Slope

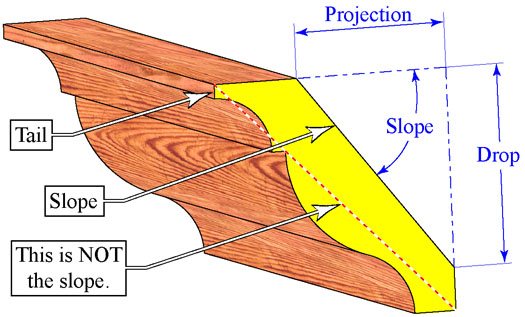

(new graphic added from

PDF) The second variable deals with the slope of the moulding

or the pitch of a roof. Most crown mouldings do not rest against

the

wall at 45°. As a matter of fact, there is no set slope for

crown mouldings. While a 38/52 moulding may be common, it is not

exclusive. The slope of the moulding is dependent on the

manufacturer

and their machine settings.

(new graphic added from

PDF) The second variable deals with the slope of the moulding

or the pitch of a roof. Most crown mouldings do not rest against

the

wall at 45°. As a matter of fact, there is no set slope for

crown mouldings. While a 38/52 moulding may be common, it is not

exclusive. The slope of the moulding is dependent on the

manufacturer

and their machine settings.

While you may know the slope when dealing with a doll house roof,

chances are, you won't know the slope of a specific crown

moulding.

Because of this I have rearranged the equations so that you can

use

Drop-Projection-Width, or just the slope. (Important Note:

Notice that when measuring these variables, they are measured with

respect to the flat side on the back of the moulding. This is

because

the flat side is the surface you place against the saw's table

when

you cut it. If you measure from the face of the moulding, the

slope

of the moulding will be wrong.) Since the Drop-Projection-Width

equation is probably the most useful, I will start with that one.

A couple new graphics from the PDF version:

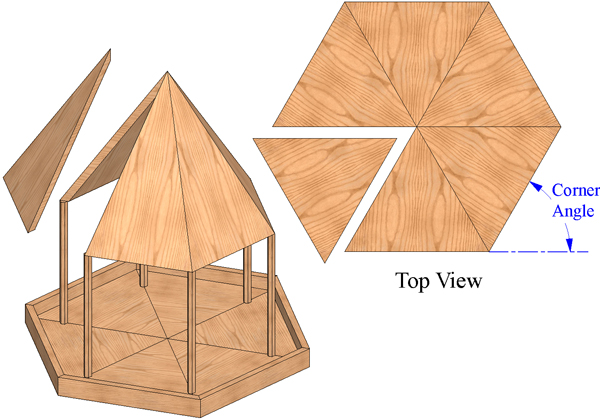

The "Corner Angle" in the

second graphic is a better way of describing the method for

finding the "Flat Miter"

in this original HTML article. The FlatMiter is 1/2 of the Corner

Angle. The Corner Angle is 360 divided by the number sides, and

the Flat Miter is 1/2 of that.

Drop-Projection-Width

If you feel more comfortable holding a tape measure than you

do

with a calculator, then this method is the best. Using a framing

square, measure the Drop, Projection and Width as shown in the

above

drawing. Then apply this into the following Equations:

Slope

If you are familiar with geometry, you may recognize the

"Drop/Width" as the Sine of an angle, and the "Projection/Width"

as

the Cosine of an angle. Just by replacing this information into

the

above equations, we end up with the following:

Unless you are building a three sided box, your miter and bevel

settings should never be greater than 45°. Furthermore,

the calculated compound miter angle should never be equal to or

larger than a flat miter setting.

As I said earlier, these equations can be used for more than just

mouldings. I have used them for many different applications when I

needed a compound angle. The key to this is to visuallize what

your

setup would be like if it was a simple moulding. In otherwords,

picture your application as though it was a moulding placed in the

corner of a room up at the ceiling.

If you found this article from a search engine, and would like to

jump to the Waterfront Woods Home page, click on the image below.

Email

Rick Christopherson

Copyright 1998, Rick

Christopherson

Email

Rick Christopherson

Copyright 1998, Rick

Christopherson

FlatMiter

FlatMiter (new graphic added from

PDF) The second variable deals with the slope of the moulding

or the pitch of a roof. Most crown mouldings do not rest against

the

wall at 45°. As a matter of fact, there is no set slope for

crown mouldings. While a 38/52 moulding may be common, it is not

exclusive. The slope of the moulding is dependent on the

manufacturer

and their machine settings.

(new graphic added from

PDF) The second variable deals with the slope of the moulding

or the pitch of a roof. Most crown mouldings do not rest against

the

wall at 45°. As a matter of fact, there is no set slope for

crown mouldings. While a 38/52 moulding may be common, it is not

exclusive. The slope of the moulding is dependent on the

manufacturer

and their machine settings.